How to Find Reliable Injection Molding Services in China

Well, the major meeting has just concluded. your new product has been approved, time is pressing, and funding is, to put it mildly, limited. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Of course, you acknowledge. On paper, it’s logical. The cost savings can be huge. Yet your thoughts are already spinning. You know the rumors, don’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It feels like walking a thin line between big savings and total project failure.

However, here’s the reality. Procuring plastic mold needn’t be a roll of the dice. It’s no different from any structured project. And like any project, it succeeds or fails based on the process you follow. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Ignore the nightmare anecdotes. Let’s walk through a real-world playbook for getting it right.

Initial Step: Prepare Your Information

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” The replies will range from absurdly low to exorbitant, none of which help.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

What belongs in your RFQ?

Start with your 3D design files. These are non-negotiable. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

However, 3D alone won’t cut it. You also need detailed 2D drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. Any seal surfaces or critical hole sizes must be clearly labeled.

Then specify the material. Don’t just say “Plastic.” Don’t even just say “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because resin grades number in the thousands. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

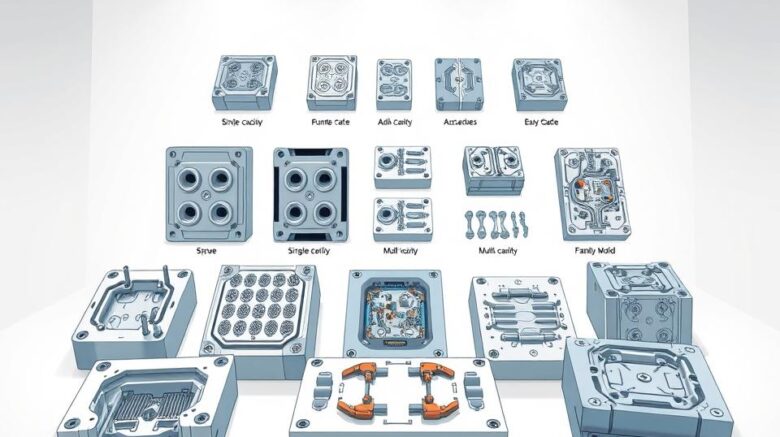

Don’t forget the commercial info. State your EAU. A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

Hunting for the Best Supplier

Now that your RFQ is pristine. who gets your RFQ? The internet has made the world smaller, but it’s also made it a lot noisier. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. They offer breadth but not depth. But think of them as a starting point, not the finish line. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

But don’t stop there. Perhaps hire a local sourcing specialist. They do cost extra. Yet top agents deliver reliable, audited suppliers. They are your person on the ground, navigating the language and cultural barriers. As a newcomer, this offers priceless security. It’s schedule protection.

Another classic method? Trade shows. With budget permitting, Chinaplas or similar shows are invaluable. Meeting onsite is unbeatable. Hold samples, talk shop, and gauge professionalism firsthand. Plus, ask peers for referrals. Consult trusted colleagues. A solid referral can be more valuable than any ad.

Sorting the Contenders from the Pretenders

With your RFQ dispatched to dozens of firms, estimates roll in. You’ll see ridiculously low offers and steep quotes. Your job now is to vet these companies and narrow it down to two or three serious contenders.

What’s the method? It involves both metrics and gut feel.

Begin with responsiveness. Are their replies prompt and clear? Can they handle detailed English exchanges? The true litmus: are they raising smart queries? Top vendors will critique and inquire. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” That’s a huge positive sign. You know they know their stuff. A supplier who just says “No problem” to everything is a walking red flag.

Afterward, verify their technical arsenal. Ask for a list of their equipment. Seek samples or case studies of comparable projects. A small-gear shop won’t cut it for a big housing.

Then comes the audit. Skipping this is a mistake. Just as you interview hires, audit suppliers. Either visit in person or engage a local audit service. They dispatch an on-site auditor for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

Transforming CAD into Real Parts

You’ve selected your partner. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the real fun begins.

Initially, expect a DFM report. DFM means Design for Manufacturability. It’s their professional review of your CAD. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A detailed DFM shows expertise. It becomes a joint effort. Together, you tweak the design for best manufacturability.

When you greenlight the DFM, they machine the mold. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are the very first parts off the new tool. It’s your first real test.

T1 parts usually require adjustments. That’s standard process. Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold company parts arrive. It could require several iterations. Build buffer time for sample iterations.

Eventually, you will receive a part that is perfect. It matches all specs, has a pristine finish, and works as required. This becomes the “golden sample.” You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Final Steps to Mass Production

Getting that golden sample feels like the end, but it isn’t. Now comes full-scale production. How do you maintain consistency for part 10,000?

Put a strong QC process in place. Often, you hire a pre-shipment inspection service. Bring in an external QC firm. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This audit shields you from mass defects.

Finally, think about logistics. Know your shipping terms. Are you on FOB terms, where they load and you take over? Or EXW, where you handle everything from their gate? Your Incoterm selection drives landed expenses.

China sourcing is a long-haul effort. It’s about building a relationship with your supplier. See them as collaborators, not vendors. Transparent dialogue, respect, and process discipline win. It’s a challenging project, no doubt. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re set to succeed.